New Developments in Thermal Spraying Technology

Release time:

2019/07/25

Source:

Thermal spraying technology has been widely promoted and applied in China. Recent trends and characteristics include:

(1) Large-area, long-term protective technology has been widely applied. For steel structures that are long-term exposed to outdoor atmospheres, spraying lead, zinc, and their alloy coatings instead of traditional paint brushing methods, implementing cathodic protection for long-term atmospheric corrosion prevention, has rapidly developed in recent years. Large-scale projects such as television towers, bridges, highway facilities, sluice gates, microwave towers, high-voltage power transmission towers, underground cable racks, navigation buoys, and vertical shaft wells have all adopted the method of spraying lead, zinc, and their alloys for corrosion prevention. Currently, dozens of specialized spraying plants in China are engaged in this work, with an annual spraying area exceeding millions of square meters. This technology has not only been widely promoted and applied domestically but has also been successfully promoted in foreign aid projects.

(2) Using thermal spraying technology to repair and strengthen large-scale key equipment and import parts for domestic production. In recent years, there have been many successful application examples. For example: 1.7-meter rolling mill, high-speed wind turbine rotors, large extrusion machine plugs, large gears, electrode extrusion molding spray, high-power automobile crankshafts, etc. These works have solved urgent production needs and saved a large amount of foreign exchange.

(3) Application of supersonic flame spraying technology. With the development and improvement of thermal spraying technology in China, the requirements for coating quality are also getting higher and higher. In recent years, the high-velocity oxy-fuel (HVOF) method developed in the United States and other countries is a new process method for preparing high-quality coatings. Because the supersonic flame spraying method has many advantages, China has successively introduced nearly ten sets of equipment from abroad, playing an important role in various industrial sectors.

(4) Gas detonation spraying technology has been further applied. Because the particle velocity of this spraying technology can reach more than 800 m/s, the bonding strength between the coating and the substrate can reach more than 100 MPa, and the porosity is <1%, it is superior to other spraying methods in certain fields. Currently, more than 10 units have been installed in China.

(5) Oxyacetylene flame plastic powder spraying technology has developed rapidly. As mentioned earlier, many companies in China have recently manufactured oxyacetylene flame plastic powder spraying equipment. Using this technology, it has been applied in chemical storage, pipelines, the ceramics industry, mud machine plate frames, the printing and dyeing industry's guide rollers, coal industry belt conveyor cast iron guide wheels, petroleum industry injection molding equipment, and surface decoration.

2024-09-17

Visiting tens of thousands of enterprises, resolving difficulties, optimizing the environment, and promoting development; using practical and effective measures to alleviate the difficulties of enterprises and continuously enhance their confidence in development. Currently, Chengdu is deeply studying and implementing General Secretary Xi Jinping's important instructions on the work in Sichuan and Chengdu, implementing the provincial Party committee's new requirements of "five focuses" and "five new chapters", taking the task of striving to boost the economy and construction as the top priority, focusing on promoting economic stabilization and recovery, and striving to achieve effective improvement in the quality of the economy and reasonable growth in quantity. This station launches a special report on "Visiting tens of thousands of enterprises, resolving difficulties, optimizing the environment, and promoting development", continuously focusing on this long-term work.

Analysis of Thermal Spraying and Sandblasting Processes

2020-04-17

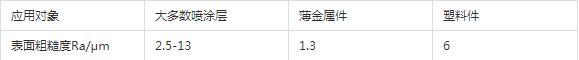

To ensure high-quality thermal spraying, thorough preparation is essential. Pre-treatment processes are closely related to the overall quality of thermal spraying. Good pre-treatment ensures good thermal spraying quality, while poor pre-treatment leads to poor thermal spraying quality. Therefore, this article focuses on the pre-treatment process of thermal spraying and provides a detailed description of the sandblasting process.

2020-03-25

The Science and Technology Service Port, in response to the technological needs of enterprises in Suining City, held a service docking and exchange activity at the invitation of the Suining City SME Service Center. This service docking and exchange activity served two purposes: firstly, it built a communication bridge between member units of the council and service enterprises, helping to promote enterprise technological improvement and providing technological solutions, thus effectively playing the role of a bridge and link for the Science and Technology Service Port; secondly, it enhanced understanding and cooperation with local public service institutions in Suining, laying the foundation for the Science and Technology Service Port to further expand its service areas, better serve SMEs in Suining, promote enterprise technological upgrading and transformation, and promote the development of the local socio-economy.