Technical services

The company is committed to becoming an expert in comprehensive surface modification technology solutions, creating a win-win situation with you.

Diamond Deposition Technology Application

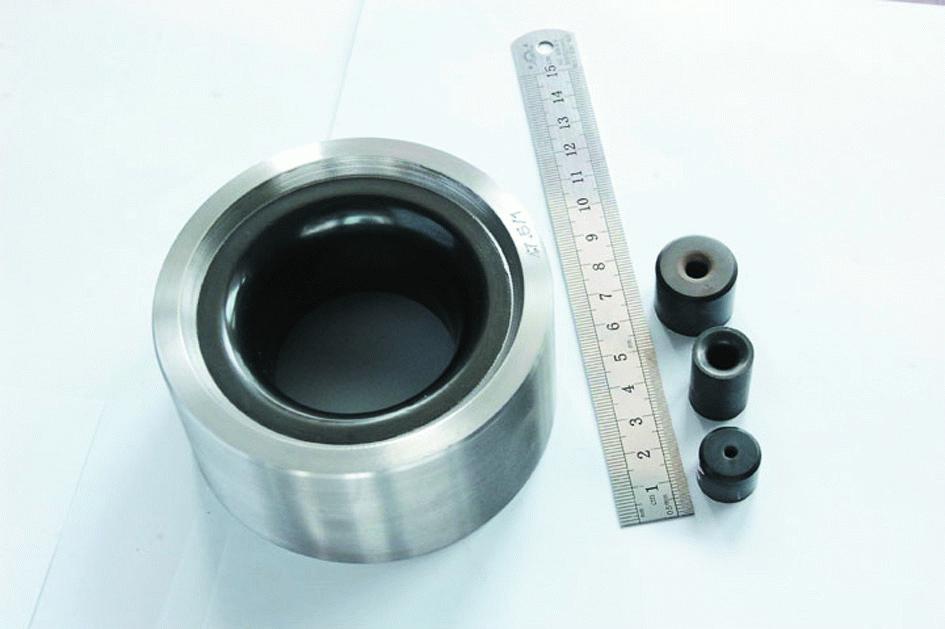

Diamond-coated wire drawing die

Using a formed cemented carbide wire drawing die as a substrate, after special surface treatment, a micron/nano diamond composite coating is grown in its working area.

Performance characteristics: It combines the high strength of cemented carbide, the super wear resistance of diamond, and the low roughness of nanocrystals. Drawing aluminum wire is more than 30 times that of cemented carbide dies; drawing low-carbon steel wire is more than 20 times that of cemented carbide dies; drawing medium-carbon steel wire is more than 30 times that of cemented carbide dies. Die wear aperture change: 0.00 mm, the working surface of the die that does not require repair has high smoothness and consistently high dimensional accuracy.

Economic benefits:

1. Reduces the number of shutdowns for inspection and die changes, improving production efficiency

2. Saves raw materials, the length of the metal wire produced is 1%~2% longer than that of traditional dies

3. Improves product quality (due to high surface finish and dimensional accuracy)

|

|

Product Case

Contact Information

Telephone:+86-13072877883

Mailbox:qfxcswb@163.com

Address: Building 5, New Economic Industrial Park, Jianzhou New Town, Chengdu

Qifeng focuses on the research and promotion of surface modification technology of various parts, and can provide a full range of surface modification design and manufacturing. Products in corrosion resistance, wear resistance, low friction, fatigue resistance, high temperature and other aspects of excellent performance.

Sichuan Qifeng New Material Industry Development Co., Ltd.

CopyRight©2025 Sichuan Qifeng New Material Industry Development Co., Ltd. All Rights Reserved