Technical services

The company is committed to becoming an expert in comprehensive surface modification technology solutions, creating a win-win situation with you.

Diamond Deposition Technology Application

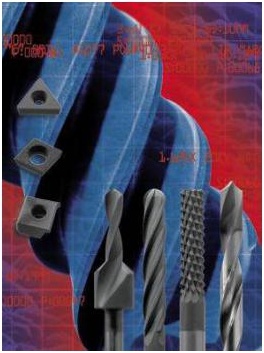

Diamond coated cutting tools

Features: Diamond-coated cutting tools have the advantages of extremely high hardness and wear resistance, low friction coefficient, high elastic modulus, high thermal conductivity, low thermal expansion coefficient, and low affinity with non-ferrous metals.

Application range: Used for precision machining of hard and brittle non-metallic materials such as graphite, high wear-resistant materials, composite materials, high silicon aluminum alloys, and other ductile non-ferrous metal materials.

Service life: Mainly depends on the material being cut, the feed rate and cutting speed selected, and the geometry of the workpiece; The service life of diamond-coated cutting tools for processing graphite is 10-20 times that of uncoated cemented carbide tools, and may even be longer in some cases. There is no need to change the tool due to wear, avoiding processing interruptions and recalibration;

When processing difficult-to-machine composite materials such as high-density glass fiber, carbon fiber, and Gl0-FR4, the service life of diamond-coated cutting tools can be as high as 70 times that of uncoated cemented carbide tools.

|

|

Product Case

Contact Information

Telephone:+86-13072877883

Mailbox:qfxcswb@163.com

Address: Building 5, New Economic Industrial Park, Jianzhou New Town, Chengdu

Qifeng focuses on the research and promotion of surface modification technology of various parts, and can provide a full range of surface modification design and manufacturing. Products in corrosion resistance, wear resistance, low friction, fatigue resistance, high temperature and other aspects of excellent performance.

Sichuan Qifeng New Material Industry Development Co., Ltd.

CopyRight©2025 Sichuan Qifeng New Material Industry Development Co., Ltd. All Rights Reserved