Surface treatment technology and thermal spraying technology development prospects

Release time:

2019/07/25

Source:

In recent years, metal surface treatment technology has rapidly developed and has been widely used in many fields. In surface treatment technology and engineering, pretreatment plays a crucial role.

Surface treatment engineering integrates the basic theories, technologies, and latest achievements from multiple fields. Surface engineering technology creates a coating or film on the surface of the substrate material or modifies the surface to give the material many special properties, making the surface properties of the material far superior to the substrate material. This not only greatly expands the application fields of the substrate material but also solves problems where materials cannot meet environmental requirements in many fields. Surface engineering technology plays an irreplaceable role in solving common problems encountered in human development, such as resources, energy, and the environment.

Surface treatment technology and thermal spraying technology save energy and materials, thus protecting precious resources upon which human survival depends, and also play a crucial role in environmental protection. In the 21st century, surface engineering technology will permeate all walks of life, promoting social civilization and improving the quality of life.

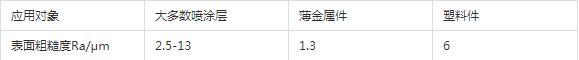

Thermal spraying technology is an important branch of surface engineering. It uses heat sources such as flames, electric arcs, or plasma to heat a certain type of wire-like and powder-like material to a molten or semi-molten state, and accelerates the formation of molten droplets that are sprayed at high speed onto the substrate to form a coating. The coating has excellent properties such as wear resistance, corrosion resistance, high temperature resistance, and heat insulation, and can repair the reduction in part size caused by wear, corrosion, or machining errors. The applications of thermal spraying technology mainly include four aspects: long-term corrosion protection, mechanical repair and advanced manufacturing technology, mold making and repair, and the production of special functional coatings. Currently, thermal spraying technology has been widely used in almost all industrial fields and household products (such as non-stick pans, infrared health electric heaters, etc.).

At the end of the 20th century, surface treatment technology and thermal spraying technology developed rapidly and were quickly promoted. By the end of the 20th century, plasma spraying still dominated. It is noteworthy that high-velocity oxy-fuel (HVOF) spraying developed rapidly and will account for 25% of the market share, ranking second. Arc spraying technology, due to its good economy and superior coating properties compared to flame spraying, will partially replace flame spraying technology and rise to third place.

2024-09-17

Visiting tens of thousands of enterprises, resolving difficulties, optimizing the environment, and promoting development; using practical and effective measures to alleviate the difficulties of enterprises and continuously enhance their confidence in development. Currently, Chengdu is deeply studying and implementing General Secretary Xi Jinping's important instructions on the work in Sichuan and Chengdu, implementing the provincial Party committee's new requirements of "five focuses" and "five new chapters", taking the task of striving to boost the economy and construction as the top priority, focusing on promoting economic stabilization and recovery, and striving to achieve effective improvement in the quality of the economy and reasonable growth in quantity. This station launches a special report on "Visiting tens of thousands of enterprises, resolving difficulties, optimizing the environment, and promoting development", continuously focusing on this long-term work.

Analysis of Thermal Spraying and Sandblasting Processes

2020-04-17

To ensure high-quality thermal spraying, thorough preparation is essential. Pre-treatment processes are closely related to the overall quality of thermal spraying. Good pre-treatment ensures good thermal spraying quality, while poor pre-treatment leads to poor thermal spraying quality. Therefore, this article focuses on the pre-treatment process of thermal spraying and provides a detailed description of the sandblasting process.

2020-03-25

The Science and Technology Service Port, in response to the technological needs of enterprises in Suining City, held a service docking and exchange activity at the invitation of the Suining City SME Service Center. This service docking and exchange activity served two purposes: firstly, it built a communication bridge between member units of the council and service enterprises, helping to promote enterprise technological improvement and providing technological solutions, thus effectively playing the role of a bridge and link for the Science and Technology Service Port; secondly, it enhanced understanding and cooperation with local public service institutions in Suining, laying the foundation for the Science and Technology Service Port to further expand its service areas, better serve SMEs in Suining, promote enterprise technological upgrading and transformation, and promote the development of the local socio-economy.